The

Lift &Tilt Tables are specifically designed to allow an operator to feed

and unload parts from tote boxes or containers quickly and easily without

lifting, bending, stretching, or reaching.

When in its lift and tilt position, the unit holds totes or containers at a

comfortable working height and angle that allows operators to easily reach

parts even at the bottom of the container.

The working table is elevated by means of a foot actuated hydraulic cylinder.

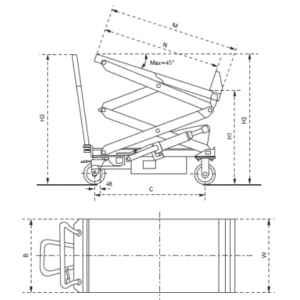

As the table is raised, it automatically tilts to an angle of 45 at full

elevation. Built-in retaining lip keeps containers in place.

Design with overload protection, safe and reliable.

| Model | BL15 | BL40 | BL80 | |

|---|---|---|---|---|

| Capacity | (kg) | 150 | 400 | 800 |

| Table Size | TxW (mm) | 830×500 | 830×520 | 830×520 |

| Dimensions | M (mm) | 830 | 830 | 930 |

| N (mm) | 748 | 830 | 830 | |

| Table Height | H1(min/max) (mm) | 415/880 | 435/900 | 440/1000 |

| H2(min/max) (mm) | 415/1400 | 435/1560 | 438/1570 | |

| Handle Height | H3 (mm) | 1100 | 1130 | 1130 |

| Wheel Dia. | (mm) | Φ125 | Φ150 | Φ150 |

| Overall Size | BxC (mm) | 500×1010 | 520×1355 | 520×1355 |

| Foot Pedal to Max. Height | 20 | 55 | 80 | |

| Net Weight | (kg) | 92 | 123 | 145 |

More easier for loading and unloading operations by means of ball transfer unit. As the steel balls are raised, the goods on table are very easy to move into or move away. As the steel balls are lowered, the goods stay on table firmly.

Internal power pack equipped with relief valve against overloading and compensated flow valve for controlled lowering speed. Suitable for using in repairing, manufacture, wrapping, assembly line place, etc.

Step-less speed regulator and integrated hydraulic pump stations to ensure a smooth lifting powerful and high power drive. Heavy duty cylinders with drainage system and anti-exploded valve to stop the lift table lowering in case of hose burst. With anti-pinch and overload protection function.

Copyright 2025 Design & Developed by Olift Equipment